|

St. Louis Flying Club Newsletter - 21 May 2008 |

From The President - By Todd Michal

Dear Members,

Thanks to John, Mike McBride, Paul, Randy, and Marlin for helping with the annual and engine monitor installation this year. Having the hangar was great as the weather was windy, rainy and cold during the annual.

Thanks to Mike Russell for renewing the insurance with Avemco for the period of June 18, 2008 through June 17, 2009. We kept the insured value of the plane the same as last year at $60,280. The cost of the insurance policy is $3,276 which is also the same as last year.

Happy Takeoffs!

Todd

![]()

Treasurer's Report - by Mike McBride

Treasurer's Report - by Mike McBride

The 2008 Annual inspection was completed within the allocated costs, quite a financial accomplishment given that we also installed the engine monitor and set up the hangar with essentials. The annual activity did not seem to adversely affect flight hours during the month.

The retail rate for fuel at JetDirect has risen by about $0.40 to $5.47 per gallon; our hourly flight rate is now $71. Fuel at Sycamore is slightly lower than at JetDirect so feel free to use either at this point for refueling. I'll try to keep you posted on any pricing disparities that arise during the month. If you can get to Festus or St. Charles County to refuel, you'll realize a price break of up to $1.00 per gallon.

Upcoming expenses include club insurance renewal and the GPS database subscription renewal. Our escrow should have adequate funds in place to cover those expenses.

With the new engine monitor, you will be able to see your instantaneous fuel consumption rate, as well as fuel remaining (assuming the unit is reset to "full" when the tanks are filled). You might want to review the Pilot's Guide (link on club web page) to familiarize yourself with the leaning and display procedures. The unit has a lot of capability, and if not careful can pull a good bit of the pilot's focus inside the plane!

Fly Safely!

Mike

![]()

Maintenance - by John

- Replaced baggage door lock with new lock and adjusted latching mechanism. (New baggage door keys are hanging on the workbench pegboard)

- Replaced lower row of circuit breakers and auto pilot, Alt Field breakers with new breakers

- Rewired landing light circuit from circuit breaker & switch to the disconnect plug.

- Repaired loose carb heat support arm on Carb air box

- Replaced gaskets on LH and RH Fuel Filler caps

- Replaced worn engine baffle seal

- Serviced Battery

- Changed Oil and filter

- Replaced ELT batteries (good now until Mar 2014)

- Greased LH and RH main wheel bearings.

EDM-700 Engine Monitor - The engine monitor with fuel flow and oil temperature was installed. In the photo below, the monitor is in lean find mode and is showing the cylinder with the highest EGT (number 4) at 1537 deg and the fuel flow of 8.4 gallons per hour as the mixture is leaned. We connected the Engine monitor to the GNS-430 using the spare RS232 we had wired into the harness when we installed the GPS. We are working to get the two units to talk to each other so we can get "fuel required to destination" and "Miles per gallon" on the engine monitor. When we download the engine monitor data from the first several flights, we will provide baseline data on what temperatures are "normal" for our engine so we can tell when something is not right.

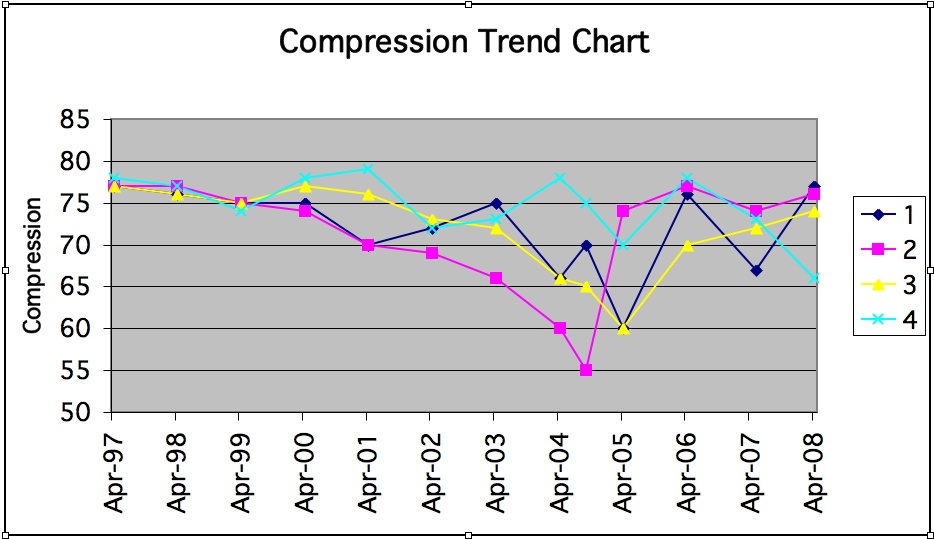

Compression Test - The compression test results show #1 at 77, #2 at 76, #3 at 74, and #4 at 66. The compression results can vary from inspection to inspection due to ring gap alignment differences and engine temperature. When we do the first cylinder (cylinder #1) just after engine shutdown, the engine is at its hottest. By the time we get to check cylinder #4, the engine has cooled somewhat which can reduce the readings. An example of how much they can change from check to check is that Cylinder #1 was 67 last year and is now 77. We will re-check Cyl #4 in 25 hours to see if 66 is a representative reading.

![]()

Copyright © 1999, St. Louis Flying Club, All rights reserved. Last updated May 2008.