|

St. Louis Flying Club Newsletter - 30 October 2016 |

From The President - By Charley

Dear Members:

Dear Members:

It was great to see everyone as our recent club meeting! Thanks to all who could make it and also thanks to those who could not but gave proxy votes. We changed up the officer ranks a bit and I’m happy to welcome Tim Volk to the position of Secretary. T.J. our previous VP has agreed to serve in the role of Treasurer and Steve Heidenreich will take the role of Vice President. Thanks to you all for your willingness to serve in these important roles!

Thanks to Geoff Gallaway for arranging lunch afterwards, we had two prospective members show up and it is always great to have some time together outside of the meeting.

I’d also like to say a huge thank you to Pic for his long tenure as Treasurer. Pic has been instrumental in too many improvements to our club to mention here and his service in the role of Treasurer has set us up very well for long term financial health. His leadership in this role has not only enabled us to add aircraft to the club along with numerous upgrades to those aircraft, but has put us in a position where we have a strong balance sheet, good financial controls and well organized information we can use to make timely decisions about club finances. Thanks for your service Pic!

There were many topics discussed during the meeting and I’d like to say a huge thanks to Dom Bausano who agreed to record minutes in Steve’s absence. Don sent the Minutes from the meeting to you by email.

T.J. and Pic have already transitioned the Treasurer role and you will see on the statement prepared by T.J. that there is the agreed to assessment of $430 that will be paid by each member this month. During the meeting we agreed to add a 23rd member and incur a $430 per member assessment to pay for the shortfall required to replace the Arrow engine. As with all projects like this, we typically decide to replace many ancillary items that are easy to get to during the replacement which often times causes the cost to rise above allocated amounts.

John, Larry and Dom have already made huge progress on the engine replacement and are expecting the project to be completed sometime in early December. You may have noticed also that the Cessna annual was completed in record time again this year, even in the midst of the Arrow overhaul. Thanks to John, Larry, and Jim and all who helped make that happen so quickly!

I’m also happy to report that John Housley will be joining us as our 23rd member. I expect that transition to be complete the week of November 7th when he returns from vacation.

Thanks to everyone who contributes so much to make our club a great place to be!

Safe skies,

Charley

![]()

Treasurer's Report - by T.J

Treasurer's Report - by T.J

Members,

A big thank you to Pic for the years of service as the treasurer! He’s not free yet though, many thanks for the hours of help in transitioning he has already invested; more to come.

Fuel crept up on us this month going from $5.86 a gallon in the September period to $6.08 in the current period, resulting in the hourly rate being $64, $79 and $104 for the Citabria, Cessna, and Arrow, respectively. It’s a great month for transition as the maintenance team has ramped up the spending getting the Cessna through its annual and getting the Arrow ready for her new engine! As voted upon by the membership at the meeting on October 15, 2016, the share value of $10,355 will be used for the month and for admitting our new member. In addition, the original 22 members will all be assessed $430 to cover the shortfall in the Arrow engine fund.

I look forward to serving the club and please don’t hesitate to contact me with questions.

T.J.

![]()

Maintenance - by John

N8746V Citabria 7ECA

- Transponder/AnnualInspection - The GTX-335 ADS-B out Transponder was ordered and the annual inspection (due in November) will start when the transponder ships.

N20843 Cessna 172M

- Annual Inspection - The annual inspection was completed on 22 October. The compression test was good with readings of #1-76/80, #2-77/80, #3-77/80, #4-77/80. The following items were replaced/inspected during the annual:

- 500 hour Magneto Inspection - The magnetos were removed and the 500 hour magneto inspection was performed. The LH Magneto was in good shape and only needed the points and cam replaced and internally timed. The RH magneto had some oil inside and was replaced with the RH magneto from the Arrow that just had the 500 hour inspection done. The RH magneto was reinspected and internally timed. After checking both magnetos on the magneto test stand, the magnetos were installed on the engine.

Fuel Sender Gage Gaskets and Fasteners - When the aircraft doors were opened after refilling the tanks, there was initially a faint smell of avgas. Larry traced this to the gaskets for the fuel quantity senders. Jim replaced the old gaskets with new gaskets and the attaching fasteners with new fasteners with o-ring washers and fuel no longer seeps out when the tanks are full. Since the gaskets were replaced, there is no longer a smell of fuel when initially opening the aircraft doors.

RH Tire - The right hand tire and tube were replaced with a new tube and tire. The RH wheel bearings were re-greased and the RH brake pads replaced.

Elt - ACK issued a Service Advisory that said "large amounts of static electricity would buildup in the external whip antenna and travel down the coaxial cable and into the ELT sometimes disabling the amplifier for the 121.5 MHz portion only. The ELT’s 406 signal will remain fully functional, however the 121.5 signal power will be diminished, and barely audible over the aircraft radio."

During the yearly check of our ELT, I could barely hear the 121.5 signal indicating that our amplifier was probably damaged by static electricity. The ELT was sent back to ACK for repair and a new static suppressor was installed at the antenna base. Until the ELT is reinstalled, there is a placard on the instrument panel the says "ELT Not Installed".

- 500 hour Magneto Inspection - The magnetos were removed and the 500 hour magneto inspection was performed. The LH Magneto was in good shape and only needed the points and cam replaced and internally timed. The RH magneto had some oil inside and was replaced with the RH magneto from the Arrow that just had the 500 hour inspection done. The RH magneto was reinspected and internally timed. After checking both magnetos on the magneto test stand, the magnetos were installed on the engine.

N2242N Piper Arrow IV

- No. 4 Cylinder Loss of Power - The loss of power in Clyinder #4 was traced to worn intake valve cam lobes. This was verified by measuring the intake valve rise and taking off Cylinder #4 and visually inspecting the cam lobes.

Engine - We ordered a Lycoming Factory Overhauled IO-360-C1C6 engine that will come with a new cam and "Roller" lifters that are designed to minimize cam shaft wear which is the number one cause for engines not reaching TBO. We were notified that our engine is scheduled to ship from Lycoming on November 21st.

Engine Mount - The engine mount/Nose landing gear support structure was removed and sent to AWI for paint strip, inspection and repair. Once the engine mount was stripped, they found 6 areas that needed repairing. They are currently repairing the engine mount and should ship it back to us shortly.

Starter - We sent our Skytec starter to Skytec for an overhaul and they recommended we upgrade to a different version of their starter. They said the version we have has the solenoid mounted separately to the side of the starter and it tends to vibrate and fail more often than the newer version. Since we were having recent intermittent starter issues, we upgraded to the new starter. With the trade in of our core, the new starter was only $50 more than having our old one overhauled.

Prop Governor - Our Prop Governor was overhauled at Quality Aircraft Accessories and was found to have a flywheel that no longer met overhaul tolerances. The flywheel was replaced and the Prop Governor was returned to us.

Firewall - The paint on our firewall was peeling in many areas and was no longer protecting the galvanized steel firewall. We stripped the firewall paint and after a good cleaning, it was primed with two coats of SEM self-etching primer and two coats of Rustoleum topcoat. It looks great and will protect the firewall from rusting and will be much easier to keep clean in the future. All of the other metal parts forward of the fire wall were stripped, cleaned and repainted to protect them from corrosion/rusting.

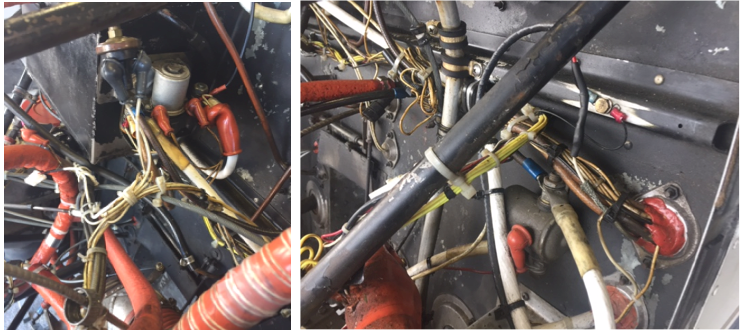

Firewall Forward Electrical - The electrical wiring and most electrical components forward of the firewall were over 37 years old and were looking pretty worn. All of the old wiring forward of the firewall and the main and starter relays will be replaced with new wiring and relays.

Hoses - Due to heat and vibration in the engine compartment, it is recommended to replace the hoses every 10 years or when you overhaul the engine. Ours were 12 years old so it was time to replace them. Aero Hose Shop in Granite City, IL was having a 50% off sale on their hoses and we were able to get a great deal on new hoses.

![]()

Copyright © 2016, St. Louis Flying Club, All rights reserved. Last updated September 2016

.