|

St. Louis Flying Club Newsletter - 30 October 2021 |

From The President - By Steve

Dear Members,

It was great to see everyone at our Fall meeting, especially being able to start it off with some great pulled pork and baked beans courtesy of John Waddell and Mike Landgraf. After eating we moved on to the meeting, starting with a "Safety Moment" from Geoff, followed by an update on the potential member waiting list and a review of the club financials. We then voted on the officer positions, which all stayed the same with the exception of the Secretary. Mike Landgraf elected to step down and we welcome Damian Mahoney as the new Secretary. Many thanks to Mike for his years of service, as well as the other members who volunteer their time and effort. Larry Wehrman did a nice job with the maintenance review that culminated with a vote to replace the audio panels in the Cessna and the Piper. We also went over options for replacing the Cessna engine when the time comes. We finished the meeting with Mike Piccirilli reviewing the member status.

After the meeting we watched Mike and Damian Mahoney depart in the RV for a multi-engine course in Arkansas. It is good to see members refreshing old skills and acquiring new ones.

The FAA is sponsoring a Safety Seminar on Saturday, October 6th at Spirit Airport in the Lieber Spirit Hangar (the Hangar next to Wings of Hope). The Seminar runs from 7:45 to 3:30 and a continental breakfast and lunch will be provided if anyone is interested in attending.

Congratulations to Charlie Royce who earned his Commercial pilot certificate and Damian Mahonney who earned his multi engine rating this month.

With the cooler weather and the Fall colors starting to pop it is a great time to go flying. I know I will be up and hope many of you are able to do the same.

Safe flying!

Steve

![]()

Treasurer's Report - by T.J

Treasurer's Report - by T.J

General Comments:

- Another great month of flying; the RV spinner replacement cut-back the hours, but not significant;

- Don’t hesitate to call with questions.

Blue Skies

TJ

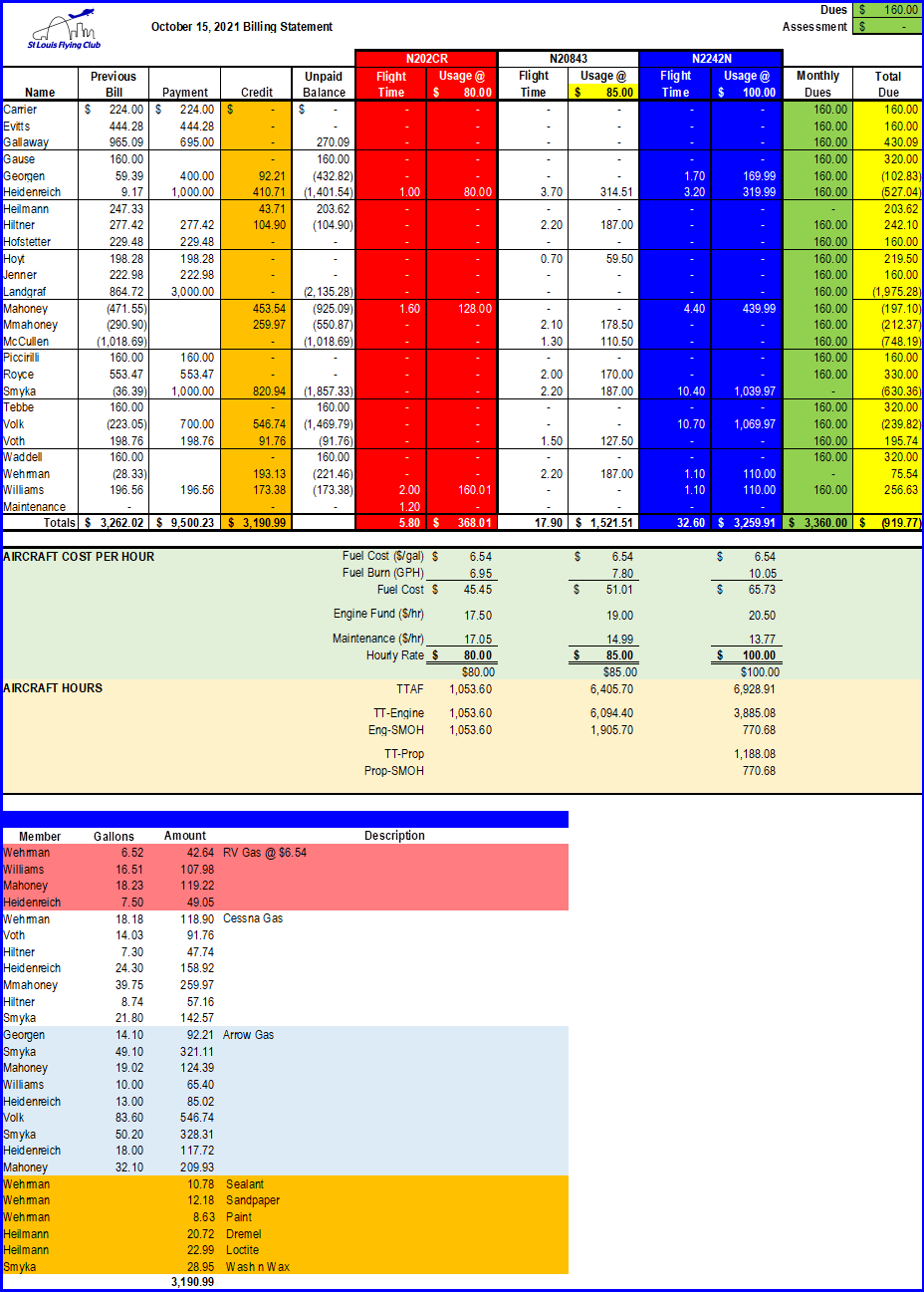

BILLING STATEMENT

BALANCE SHEET

Significant Discussions:

- Avionics Improvement - John sold several items in the month. These sales paired with large cash contributions in the month contributed to an overall large increase in cash.

- Maintenance Funds - All the maintenance funds are adequate and healthy relative to our spend rate over the past 12 months.

- Overall Cash - Cash is sufficient to operate into the foreseeable future.

- Aircraft Values - As discussed at the meeting, we will revalue the aircraft on 11/15 so we have fresh values for the January insurance renewal.

DUES

Our current dues allocation is as follows:

![]()

Engine Heater Operation - by John and Larry

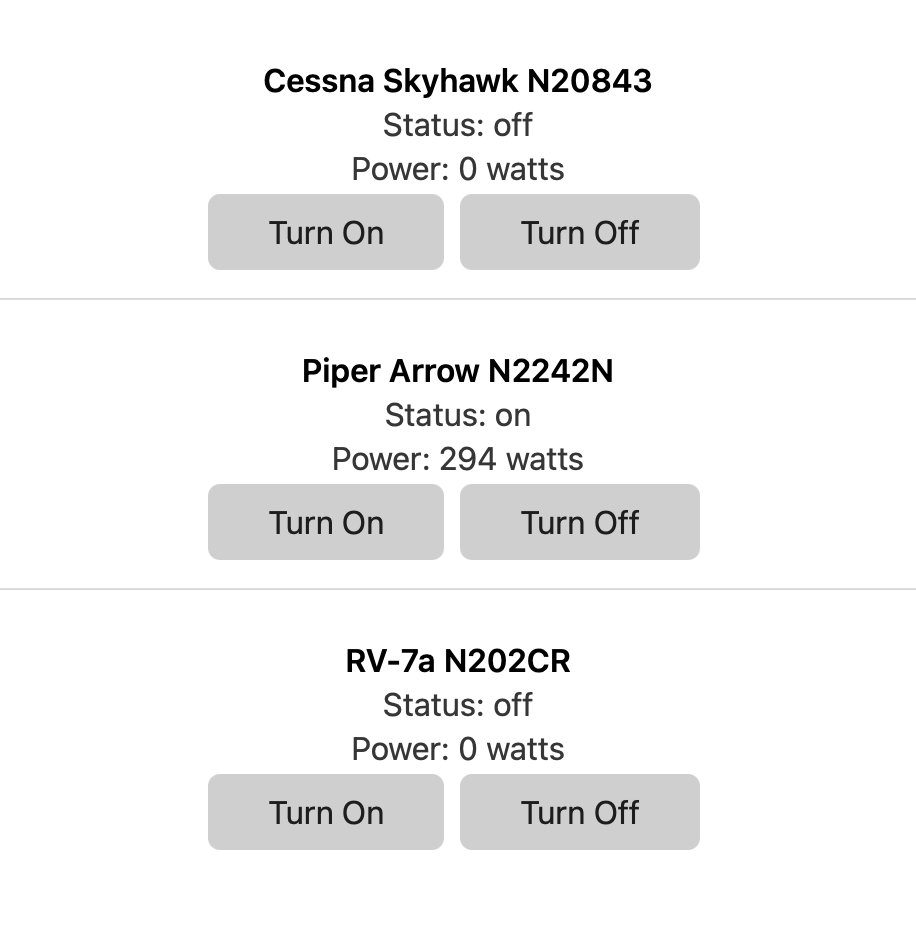

With the temperatures cooling down, we plugged in the engine heaters and put blankets on top of the cowls. The engine heaters can be controlled at the following site: heaters.geoffeg.org

You can also access the Engine Heater Control page using the "Engine Heater Controls" link on the main page of the website and also on the top of each of the plane's schedule Pages. Thanks to Geoff for setting up the Engine Heater control page and programing the WIFI controlled sockets. The following picture shows the Engine Control Page with the Arrow heater turned on. Verify that the watts is showing a value around 290 watts for the Cessna and Arrow and around 250 watts for the RV to make sure the heater is plugged in and operating.

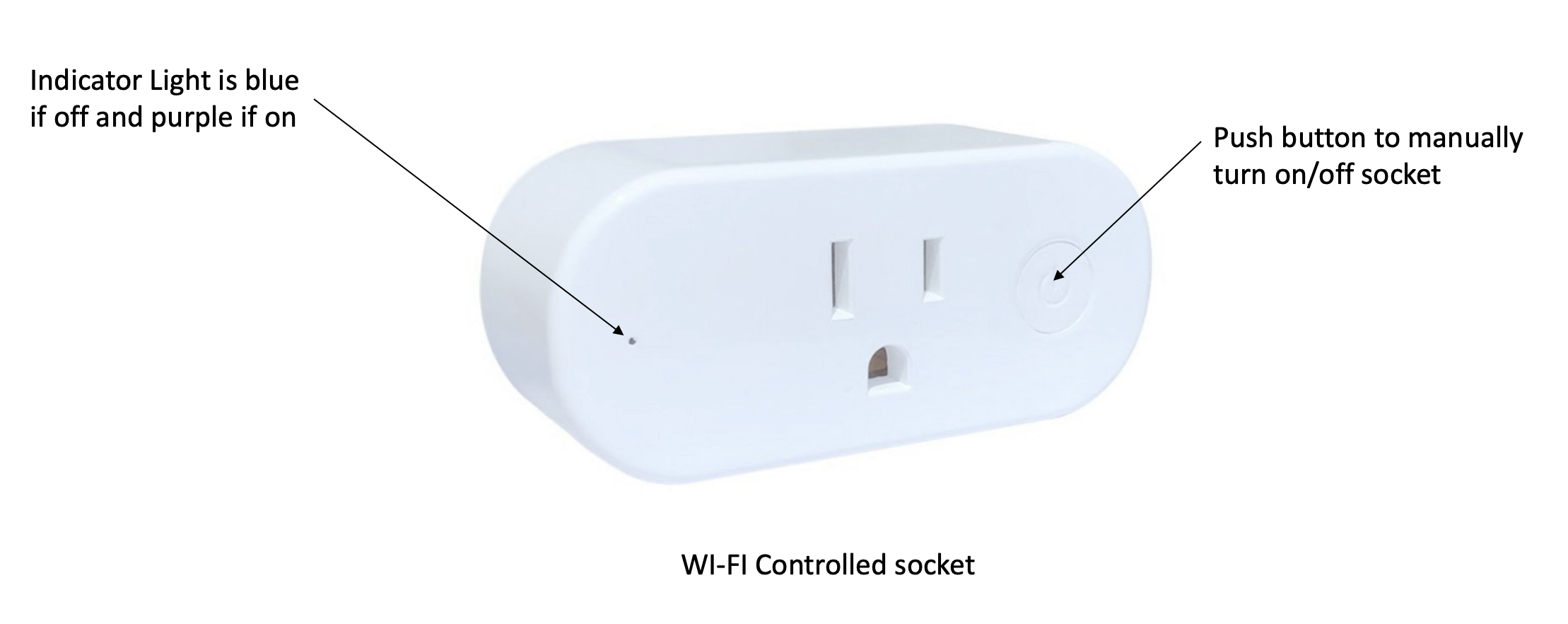

After your flight, make sure the heater is "off" when you plug the heater extension cord back into the plane unless someone else is flying after you and preheat is needed. The heater extension cords have LEDs in the socket and will be lit if the heater is turned on. You can turn the heater off with the controls on your phone/computer or press the button on the wifi controlled socket as shown below.

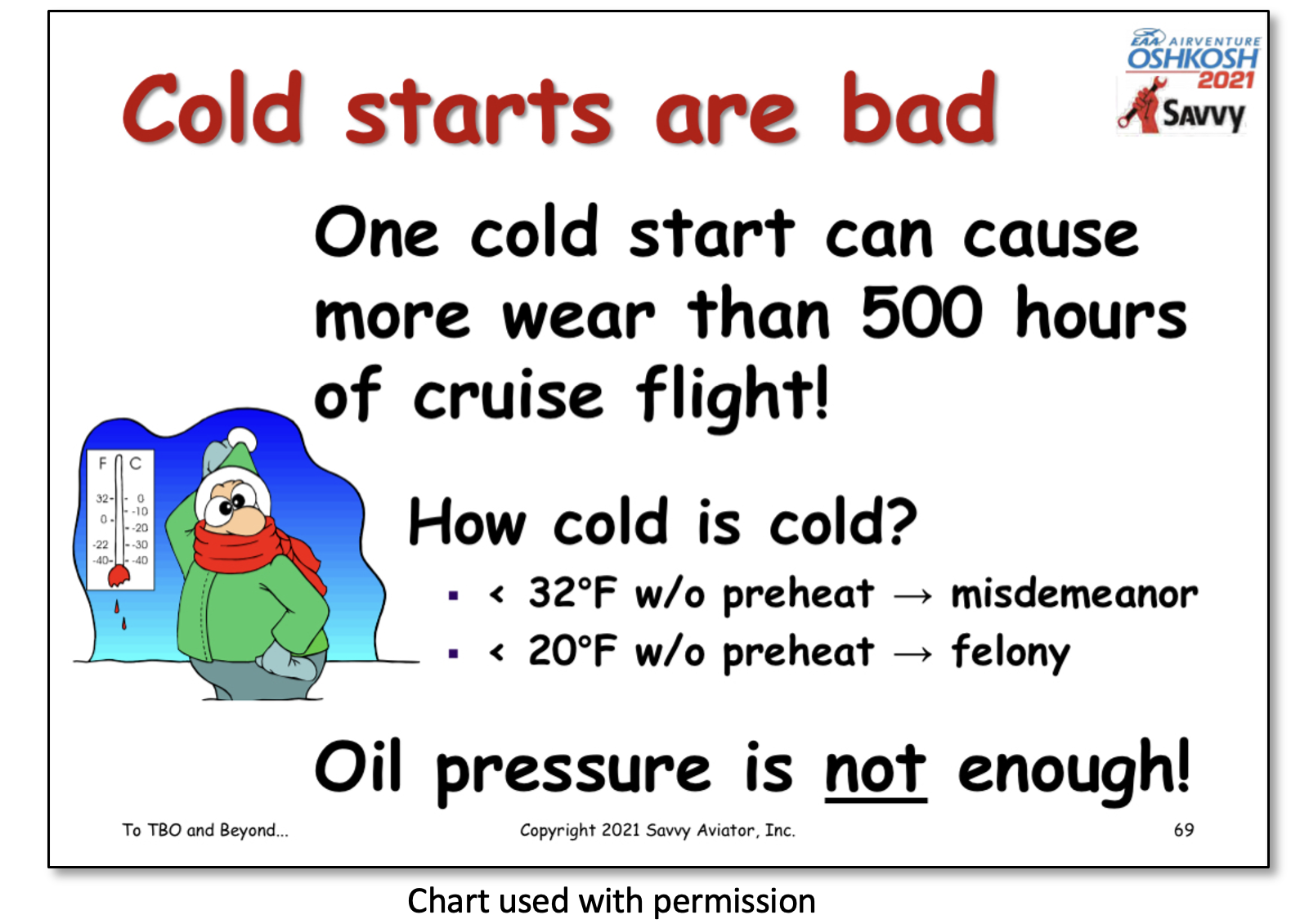

The chart below was briefed by Mike Busch at Oshkosh this year and shows how important it is to preheat when the temperatures are around 32 degrees and below. Go to TBO and Beyond to view the whole presentation which is excellent.

Since it is easy for us to remotely turn on the engine heaters, we recommend using preheat when temperatures are below 40 degrees. If you are going to fly in the morning, turn the heater on at night before you go to bed. If you are going to fly in the afternoon, you can turn the heater on in the morning.

It is also important to consider preheat needs at a destination airport. For example, if you fly to Jefferson City for breakfast and the temperature is 20 degrees, you preheated the plane before you left KSUS but if the plane sits at KJEF for an hour or more in 20 degree temperatures, it may need preheating before you start it. You can turn on the engine monitors before you start the aircraft to see what the oil and cylinder temperature are. You can take an extension cord with you and work with an FBO to plug in the heater at a remote airport if needed.

What happens if you cold start an engine? I know of a case where the plane was flying great but had to wait longer at a remote airport up north to pick up a passenger. The engine was started for the return flight without preheating and on the trip back, the engine burned 3 quarts of oil and two cylinders had to be replaced before the next flight. A friend told me yesterday that Lycomming says to preheat below 10 degrees F and that's what he has been doing. He also said he had to replace all 4 of his cylinders at around 1000 hours SMOH. When we bought the RV, cylinder No. 3 did not have a heater element installed because a CHT probe was installed where the heater element would go. When we purchased the plane, we put in a different type of engine heater so that all cylinders would be heated. The RV was previously based in Nebraska and every time the previous owner preheated the engine, all the cylinders were heated except for cylinder No. 3. We just had to replace cylinder No. 3 on the RV earlier this year and lack of preheat in the past may have been a big contributor to its early demise.

![]()

Garmin Smart Glide - by John

Garmin announced Smart Glide at Oshkosh this year and it is now working using our RV-7A G3X. Smart Glide is designed to assist you if you have an engine failure. When activated by pressing the G3X Direct To button for 3 seconds, the Smart Glide program automatically turns on the autopilot and pitches the aircraft for the RV-7A best glide speed of 80 knots. The system also looks for an airport within glide range and if there is one, it will set up a GPS direct course to the airport using the internal G3X GPS. If there is not an airport within glide range, it will announce that so you can start looking for the best field to land in. We currently have it set to look for any airport with a runway length greater than 1000 feet. When you get near the airport, the program tells you to disconnect the autopilot and maneuver and land. We have tested the system and it works great.

In the G3X screenshot below, we just simulated an engine out condition by pulling the throttle and pushed the G3X Direct To button for 3 seconds to activate the Smart Glide Mode. The normally blue glide range ring turns yellow and the Yellow Glide indication near the upper center of the screen comes on. The Smart Glide program automatically turns the autopilot on and sets up for a best glide speed of 80 kt. Since Washington Airport was in the glide ring, the program automatically sets a direct to course from your present position to Washington airport and the autopilot takes you there. The plane is slowing up through 118 knots as it slows to the best glide speed of 80.

The screenshot below shows the emergency page which is selected by pressing the yellow Glide button on the top of the screen. It shows the airport you are going to, the wind direction and speed and the runway length and surface. In this case with a calm wind, it is not telling you a specific runway to land on. If the wind was stronger and favored a particular runway, it would tell you which one would be best to land on. The Yellow Smart Glide window is telling you the Smart Glide Mode is active and the Red Maneuver and Land is telling you to turn off the autopilot and Maneuver and land the airplane. It also gives you the emergency frequency that you can select and load to one of the radios. If you want to cancel the Smart Glide Mode, there is a button to press Cancel Glide near the bottom.

When finished practicing with Smart Glide, you need to change the HSI GPS source from Internal (G3X) to External (GNC-355) so you can navigate with the GNC-355. Garmin is planning to release Smart Glide for the Certified GTN-75Xi (not our current GTN-750 units due to processor speed limitations) and the certified G3X so we can put it into our Arrow G3X. Hopefully we never have to use Smart Glide with an actual engine out situation, but if we do it can help setting you up for a more successful emergency landing.

There are some good videos on Smart Glide on YouTube and this one is good as it is close to our RV Avionics installation. Smart Glide Demo

![]()

Maintenance - by John

N202CR RV-7A

- Spinner/Sump Gasket - The installation of the new spinner and oil sump gasket was completed on 7 October and the plane was returned to service. After the first flight on 7 October, the plane was downed for a post flight check to verify that the new oil sump gasket was not leaking. We found that there was no leakage past the new sump gasket but we did find another oil leakage location. There was a small leak past the vacuum pump pad cover gasket and we decided to remove the whole vacuum pump drive assembly since it is not needed with our current configuration. This saved nearly a pound of weight and eliminates 2 potential oil leak paths.

N20843 Cessna 172M

- Fire Extinguisher - On 14 October, a new Halon Fire Extinguisher was mounted between the two front seats. There were existing fire extinguisher mounting provisions in the floor structure and we just needed to make an adapter plate to mate with the holes in the fire extinguisher mount. The fire extinguisher will be weighed periodically to verify the cylinder has the required amount of Halon.

N2242N Piper Arrow IV

- Engine Roughness - On Oct 12th, Steve reported a rough engine after starting that gradually smoothed out. He said the EGT on number 3 cylinder was late to rise compared to the other cylinders. Larry and I were at the airport and heard then rough running engine as well. Since the symptoms could indicate a fouled plug or a sticking valve, we decided to be on the conservative side and verify it wasn't a sticking valve on cylinder #3. We removed the No. 3 cylinder valve cover and valve springs. With the valve springs off, the valves moved easily in the guides which indicates the valves aren't sticking. We put the cylinder back together and ground and flight ran the engine with no issues. In this case, it was probably caused by a fouled plug but it was worth verifying that it wasn't a sticking valve issue.

- Hydraulic Pump - On Oct 18th, Geoff reported that the gear started to go down but then stopped. He raised the gear and tried to lower it again with the gear switch but it didn’t go down at all. With the gear switch left in the down position, he got the aircraft manual out and started to look at the emergency gear procedures and then the gear finally came down with three green lights. Geoff left the gear down and flew back to Spirit.

We put the plane on jacks and the first two gear retracts/extensions went normally. On the third extension try, the pump would run but the gear didn’t come down so we were able to duplicate what Geoff had seen. During troubleshooting, we found a small hydraulic fluid leak under the hydraulic pump where it attaches to the hydraulic pump mount. The leak had caused the fluid level in the pump reservoir to get low causing the gear issue Geoff had seen. Before taking the pump out to repair, we added fluid to the reservoir and the gear retracted/extended normally three times which indicates the leak/low fluid was the cause of the problem.

There are 4 O-rings that seal the joint where the leak was coming from. We replaced the O-rings and reassembled the pump to the pump mount. Proper operation of the pump/gear was demonstrated on the ground with 3 retraction/extension and in the air with 2 retractions/extensions. The Arrow was returned to service on 21 October.

![]()

Copyright © 2018, St. Louis Flying Club, All rights reserved. Last updated November 2021

.